Molded foil boards are also called Pop-Outs. The name Pop Out implies how they are made. Pop outs are not shaped but they pop-out of a mold that duplicates hundreds or thousands of foil boards. Molded foil boards construction process is the following: a female mold of a foil fboard in two halves, top and bottom, is fiber glassed. The two halves are then brought together and liquid polyurethane foam is allowed to expand to fill the void in the center. The join line is later cleaned up and finished with a strip of special tape.

Molded foil boards are durable and hard to damage, the are shaped for the beginner foilers, so you can pick up foiling easily. They are the foil boards that take you from a complete novice to basic level of foiling. The downside of the durability is weight – they are heavier than a custom board.

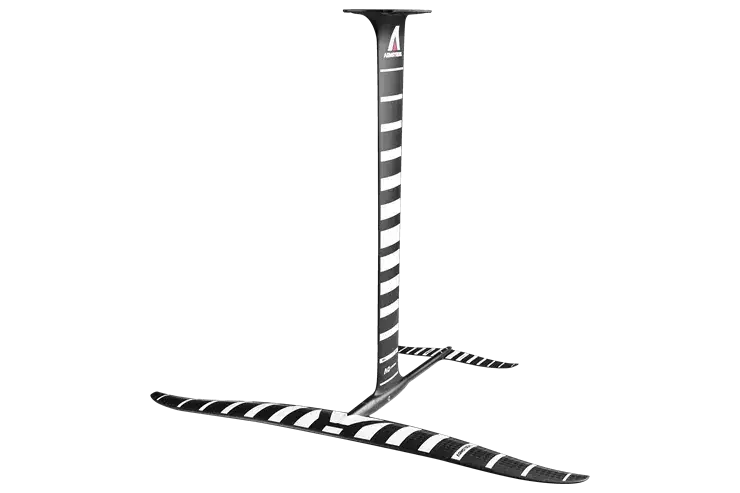

ARMSTRONG FOILS

ARMSTRONG FOILS WINGS

WINGS FOIL BOARDS

FOIL BOARDS FOILKITS

FOILKITS FRONT WINGS

FRONT WINGS MASTS

MASTS STABS

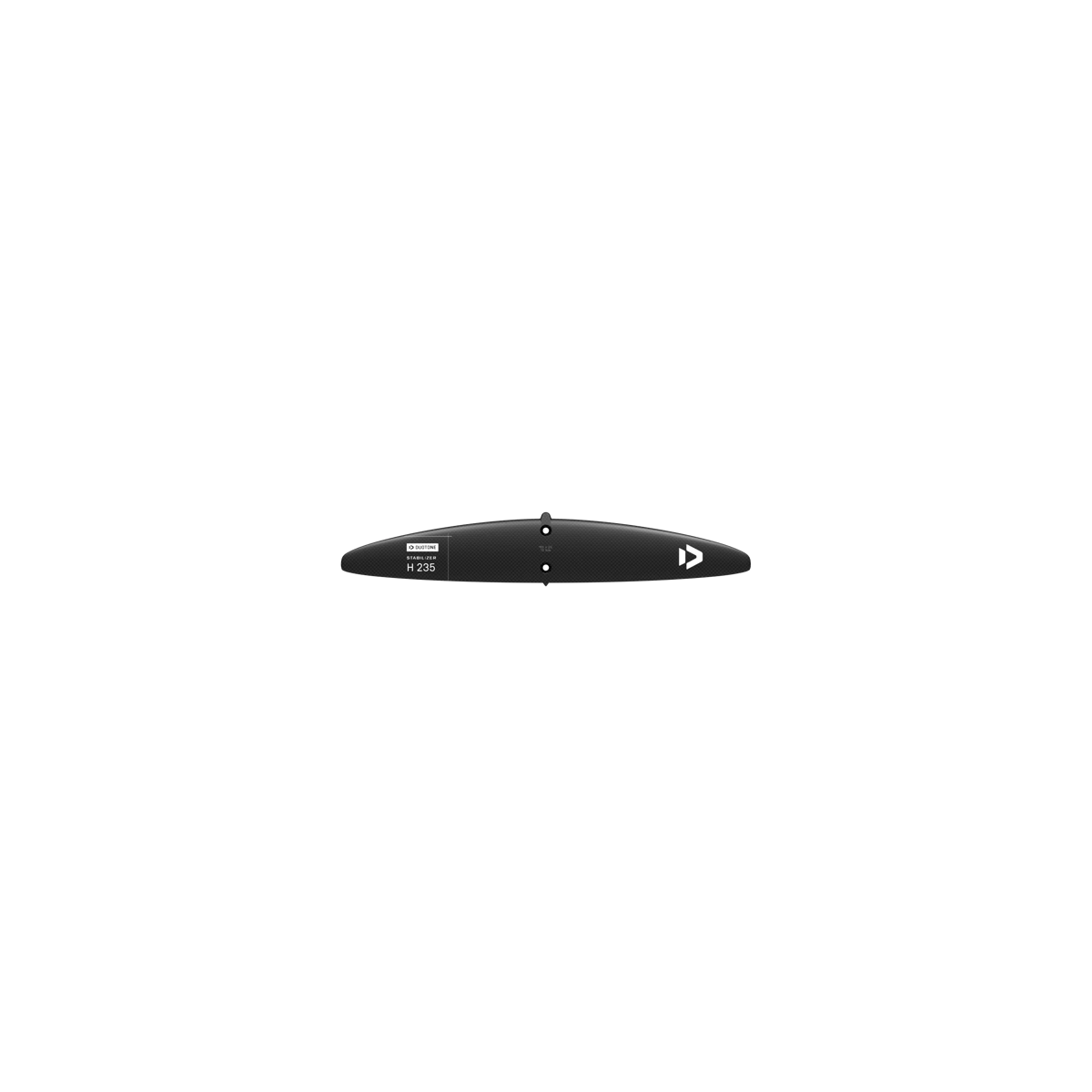

STABS DUOTONE

DUOTONE WINGS

WINGS FOIL BOARDS

FOIL BOARDS FOILKITS

FOILKITS FRONT WINGS

FRONT WINGS MASTS

MASTS FUSELAGES

FUSELAGES STABS

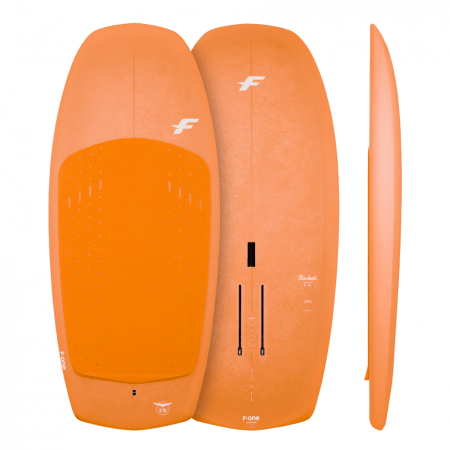

STABS F ONE

F ONE WINGS

WINGS FOIL BOARDS

FOIL BOARDS FOILKITS

FOILKITS FRONT WINGS

FRONT WINGS MASTS

MASTS MONOBLOC STABS

MONOBLOC STABS FUSELAGE

FUSELAGE STABS

STABS APPLESLICE V3

APPLESLICE V3 APPLE SKIPPER WING

APPLE SKIPPER WING JAZZ

JAZZ APPLE SKIPPER PRONE

APPLE SKIPPER PRONE PRO FOIL SURF V2

PRO FOIL SURF V2 SLINGSHOT

SLINGSHOT NXT

NXT SLINGWING V5

SLINGWING V5 LTF V2

LTF V2 ULTRAFLY

ULTRAFLY